ONE FULLY

CONNECTED DRT

CONNECTED DRT

FACILITIES

A NETWORK OF EXCELLENCE

For many manufacturers, a team of skilled machinists and state-of-the art equipment are enough. But DRT Aerospace (DRT) has taken precision manufacturing to another level, where value, technology, extensive resources and problem-solving expertise are the standard.

- Market-focused, multi-disciplined teams of problem solvers at seven specialized centers of excellence

- Resource planning systems to enhance flexibility and response

- State-of-the-art facilities and equipment

FACILITIES

AEROSPACE CENTERS

OF EXCELLENCE

OF EXCELLENCE

DRT supports customers through a network of seven AS-9100 certified facilities. This connected network ensures maximum capacity and the ability to flex work in a closed-loop environment.

FACILITIES

SYSTEMS & EQUIPMENT

ENABLE EFFICIENCY

ENABLE EFFICIENCY

We help customers meet aggressive schedules with sophisticated software and a dedicated planning system. In fact, our full-scale Enterprise Resource Planning (ERP) system is the backbone of DRT operations across all facilities. This allows us to view our entire production schedule and dynamically adapt to changing customer demands. Our ability to flexibly plan and schedule production work means better on-time delivery (above 98 percent) and translates to faster time-to-market for our customers.

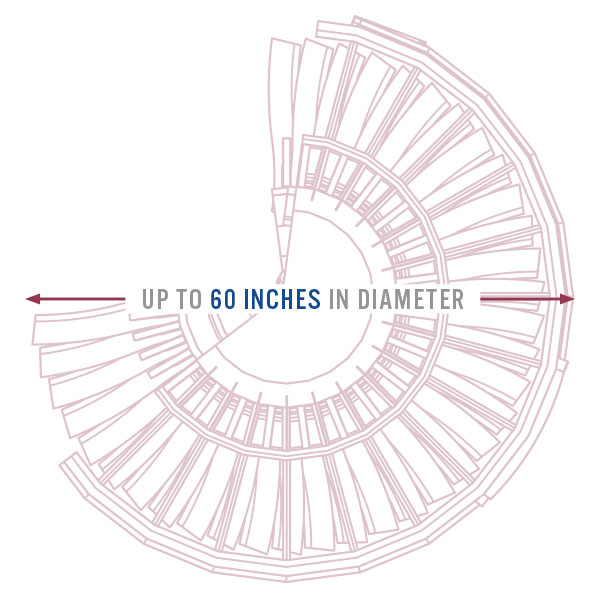

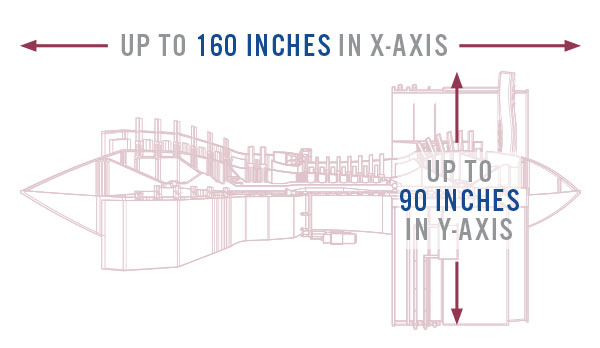

DRT’s broad range of capabilities is enabled by a wide range of machine tools. We manufacture parts smaller than ¼ inch up to 60-inch diameter and up to 160 inches in “X” by 90 inches in “Y.” Expect the latest in CNC milling and turning technology. Key equipment includes:

- 3-, 4- 5- and 7-axis mills

- Mill turns

- Multi-spindle lathes

- EDM wire/ram

- Jig grinding

- Stamping presses

- Water jet cutting